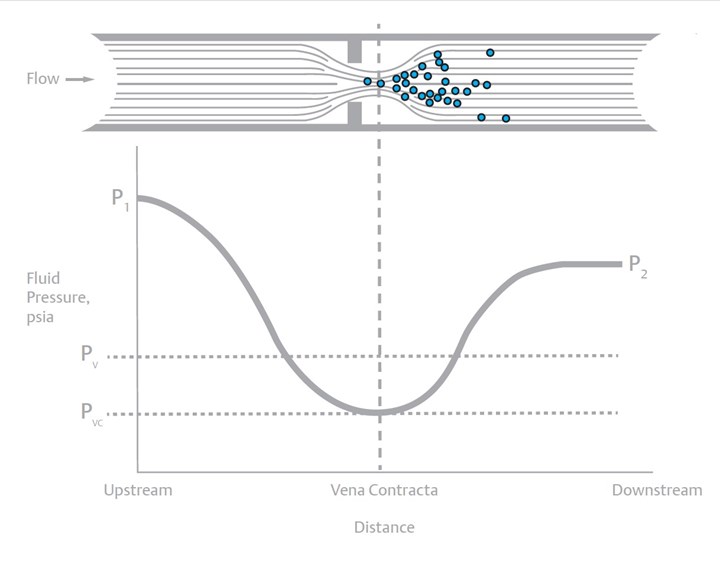

Cavitation, the downstream effect created by pressure drop as fluid moves through a valve or other restricted area, can have costly and disruptive impacts on fluid systems. In theory, the solution for cavitation is simple: manage the velocity of the fluid such that it never drops below its vapor pressure, which is what causes vapor bubbles to form and then burst when the pressure increases again.

Cavitation occurs because of pressure drop which can be caused by a change in fluid velocity. The vena contracta is the point of minimal flow and maximum velocity, where cavitation is most likely to form. Source: Emerson

But in practice, developing and manufacturing valve accessories to prevent cavitation has been difficult and time-consuming. Most solutions rely on producing and joining multiple tubes, plates or other components to produce a geometry that breaks up the stream of fluid to fight pressure drop and thus prevent cavitation. The manufacturing process for these devices can become complex, expensive and slow, requiring multiple suppliers, steps and components to come together.

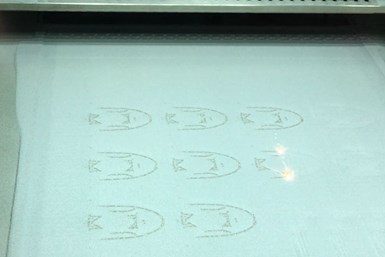

Laser powder bed fusion involves spreading a thin layer of metal powder across the printer bed, then selectively melting that material with a laser to form the geometry of the part(s). Source: Additive Manufacturing Media

The production of anticavitation devices can be made easier, however, with additive manufacturing (AM). AM is the application of 3D printing technologies to produce functional, end-use production parts within an industrial workflow. Laser powder bed fusion (LPBF), a 3D printing process that melts metal powder using laser energy to build up parts, is the process most commonly applied to valve components today. With this technology, it is possible to produce complex, optimized geometries that can take the place of assemblies. Without the need to produce and join many individual components, anticavitation devices can be manufactured with less manual labor, reduced lead times and even lower cost.

While additive manufacturing is not yet widely used in valve production, it is beginning to find use cases in anticavitation devices. Two such case studies are outlined below:

1. Emerson’s Fisher Cavitrol Hex Trim

Emerson historically offered an anticavitation rotary valve trim that was constructed from many metal tubes brazed together and machined to fit inside a ball valve. Although this device was effective, it was time-consuming and expensive to produce, and the company eventually discontinued it due to manufacturing difficulty.

Emerson’s conventionally produced anticavitation device involved many parts and skilled labor, and was difficult and costly to produce. Source: Emerson

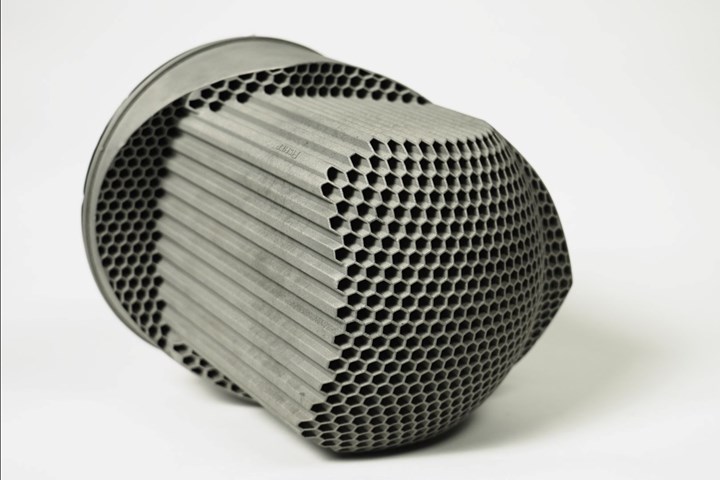

More recently, however, Emerson has used 3D printing capability to develop and manufacture a new product, the Fisher Cavitrol Hex Trim. This valve trim features a series of parallel, hexagonal tubes that break fluid into multiple streams, slowing the velocity inside the system. The geometry can be 3D printed all in one piece, with a shape that contours to the interior of valve.

“Locating the Cavitrol Hex array within the valve such that it is very close to the entrance of the throttling area limits the fluid momentum that causes the flow stream to contract,” says Brandon Bell, product marketing manager for Emerson’s Fisher Rotary Products brand. “The result is larger vena contracta flow area, reduced fluid velocity and higher vena contracta pressure, thus suppressing the onset of cavitation.”

Emerson’s 3D printed Cavitrol Hex trim incorporates hexagonal tubes and for most sizes can be manufactured all in one piece through laser powder bed fusion. Source: Additive Manufacturing Media

In addition to preventing cavitation, the division of the fluid into many smaller streams also has the effect of reducing noise and vibration, as well as straightening the flow. The hexagonal cross-sections of the tubes, which could only be realized through 3D printing, provide strength and optimized flow area for improved performance over the previous solution.

Using LPBF 3D printers from Nikon SLM Solutions, the company now 3D prints the Cavitrol Hex Trim in stainless steel and cobalt chrome at its facility in Singapore. In many cases, the trim can be 3D printed in just one piece, avoiding the brazing operations needed previously and resulting in a more reliable product. (Larger versions that exceed the build volume of the printers are printed in segments and joined.)

Emerson is also realizing the benefits of flexible design through AM. Valve trim can be modified according to customer needs much more easily by simply modifying the digital file. The company says that more than 600 Cavitrol Hex Trim products have been sold thus far.

2. Baker Hughes’ Variable Resistance Trim Stack

Baker Hughes provides a product line of variable resistance trim stacks which conventionally have been produced by literally stacking together sheets of metal with holes drilled in strategic locations. Fluid is forced through a tortuous path inside the stack, again slowing its velocity and mitigating pressure drop that can otherwise lead to cavitation.

While the variable resistance trim stack design is effective, manufacturing these devices in the variety of sizes and configurations needed has proven to be time-consuming and challenging. Producing these stacks conventionally involves machining each sheet individually, brazing them together and final machining operations on the assembly. The process required coordination with a series of vendors, frequently leading to long lead times and other challenges.

“In each one of those manufacturing steps, you have a risk of something going wrong,” says Rebecca O’Donnell, senior product manager. “When you send parts out to third party suppliers, even though they're qualified, there's still the risk of a quality issue that might occur. The purpose of doing the 3D printing is to make sure that we have total control of the part throughout. We monitor the quality and the lead times quite effectively.”

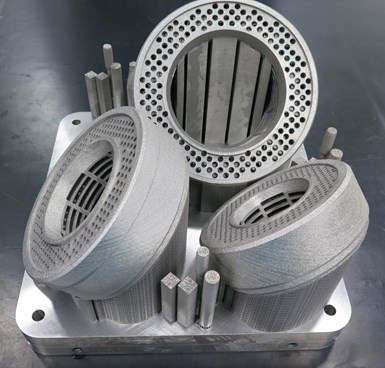

Baker Hughes now 3D prints variable resistance trim stacks all in one piece. The geometry has not changed much from the conventional stacks, but the manufacturing process has been dramatically simplified. Source: Additive Manufacturing Media

To reduce the number of steps and vendors involved, Baker Hughes now manufactures its trim stacks with its in-house 3D printing capacity located in Houston, Texas. The stacks are produced on machines from Nikon SLM Solutions in Inconel 718, and have been made in a variety of sizes. The 3D printed anticavitation devices are very similar to the conventional design, with only minor adjustments to make the 3D printing and manufacturing process easier.

Multiple trim stacks can even be 3D printed at the same time. Parts are shown here still attached to the build plate (the square piece of metal that serves as a platform for 3D printing) with the support structures that anchor them and dissipate heat during the process. Source: Baker Hughes

By converting its trim stack designs for AM, Baker Hughes is realizing significant time savings as well as other benefits. Instead of relying on outside vendors, the company now performs almost the entire workflow internally. With fewer steps and vendors to manage, and no joining operations, the potential points of failure for each trim are also reduced.

Each trim that is converted for AM is also saved within the company’s PLM system to lock it in and prevent unintentional editing; standardized production builds are further designated with a golden icon. Every part released for production has a “Golden Master Manufacturing” router that includes the golden design file, build setup file, postprocessing instructions and inspection instructions. This ensures that successful trim stack builds can be recreated at a moment’s notice, and is helping Baker Hughes meet customer needs quickly without needing to store physical parts in inventory.

“We see about a 70% reduction in lead time when it comes to 3D printing versus a traditional manufacturing method,” O’Donnell says. In emergency situations, the company has even delivered 3D printed trim stacks in as little as 2 weeks.

More From This Author

Stephanie Hendrixson reports on 3D printing technology and applications as executive editor of Additive Manufacturing Media. She contributes to Additive Manufacturing magazine and The BuildUp newsletter, and appears on the AM Radio podcast and The Cool Parts Show. SUBSCRIBE HERE.

RELATED CONTENT

-

Erosive Pulp & Paper Systems Require Proper Valve Selection

As new recycled paper plants are being built for the first time in decades, not only do paper companies have opportunities to grow revenue but so do service suppliers such as valve companies.

-

The Final Control Element: Controlling Energy Transformation

When selecting control valves, be sure to properly evaluate the process conditions to identify potential issues and select the proper management techniques.

-

New Technologies Solve Severe Cavitation Problems

An advanced anti-cavitation control valve design enabled by 3D metal printing solved a power plant’s severe cavitation problem and dramatically improved its bottom line.

.jpg;width=70;height=70;mode=crop)

Unloading large gate valve.jpg;maxWidth=214)