Siemens Announces New R&D Collaboration with Oak Ridge National Laboratory

CATCH will be the entry point for many manufacturers to understand how and why additive manufacturing is crucial to designing products more effectively, manufacturing them closer to the point of purchase and creating a more resilient supply chain.

#iiot #VMAnews #automation

Edited by Margo Ellis

Siemens announced it has engaged in early-stage research and development projects with multiple partners including National Laboratories. The Department of Energy’s (DOE) Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory (ORNL) is a pioneering institution focusing on manufacturing analysis and simulation, materials development, large-scale metal systems, robotics and automation. The collaboration between Siemens and ORNL on multiple DOE-funded projects has enabled the cooperative investigation of multiple methods of advanced manufacturing and materials solutions.

Dr. Anand Kulkarni, senior principal, Key Expert at Siemens Technology, commented, “The joint collaborative research done at MDF to address industrial problems demonstrates the success of the DOE’s MDF model and clearly shows the need for a path to industrialization through similar hubs in industry focusing on higher technology readiness levels. Siemens launched its Charlotte Advanced Technology Collaboration Hub (CATCH) to fill this void”.

“ORNL and the researchers at MDF are proud to collaborate with innovative industrial partners like Siemens to help advance and revitalize the U.S. manufacturing sector. We recognize that our DOE-funded research is often best leveraged through regional and national collaborations like CATCH and the MDF, helping to advance additive manufacturing technology, drive workforce development and create a more efficient and decarbonized manufacturing base,” said Bill Peter, Advanced Manufacturing program manager, Oak Ridge National Laboratory.

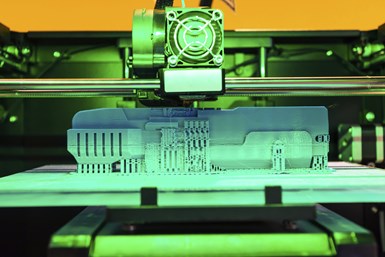

Recently, Siemens opened its new Charlotte Advanced Technology Collaboration Hub in Charlotte, NC. This new strategic research and development hub, spearheaded by Siemens Digital Industries, Siemens Technology and Siemens Energy, helps its customers accelerate their plans for the industrialization of additive manufacturing (AM). Specifically, Siemens will use this space to collaborate with key machine builders (OEMs), end-users and U.S. national laboratories to ensure the successful industrialization of additive manufacturing.

“We are excited to launch this new additive manufacturing hub and begin inviting customers in to collaborate and find ways to accelerate the industrialization of this technology using our machine-agnostic solutions,” said Tim Bell, Additive Manufacturing business manager, Siemens Digital Industries. “The benefits of additive manufacturing are clear — from faster time-to-market to better design through digital prototypes, to localized manufacturing helping to reduce supply chain constraints. We believe that future of manufacturing is additive.”

To support its customers along their journey at CATCH, Siemens has accumulated a group of world-class experts from several Siemens businesses and operating companies. CATCH will become one of seven hubs strategically placed at major AM eco-systems around the world with the distinct focus of facilitating customer AM journeys.

RELATED CONTENT

-

MSS Publishes Revised and New Industry Standards

The Manufacturers Standardization Society (MSS) of the Valve and Fittings Industry is excited to announce publication of the new Standard Practice SP-158-2021, Supplemental High-Pressure Gas Test Procedures for Valves.

-

The Final Control Element: Controlling Energy Transformation

When selecting control valves, be sure to properly evaluate the process conditions to identify potential issues and select the proper management techniques.

-

PFAS Chemicals and PTFE: Should the Valve Industry Be Concerned?

Legislation moving through Congress could affect the future use of thousands of PFAS chemicals (per- and polyfluoroalkyl). The house passed H.R. 2467 in July of 2021 and, though the bill is general in nature, it assigns the responsibility to the Environmental Protection Agency (EPA) for determining which PFAS chemicals will be controlled or banned altogether.

Unloading large gate valve.jpg;maxWidth=214)