Valmet Launches DNAe, Next-Gen Distributed Control System

The system empowers users to seamlessly run industrial applications on-premise, at the edge server or in the cloud.

#controls #automation

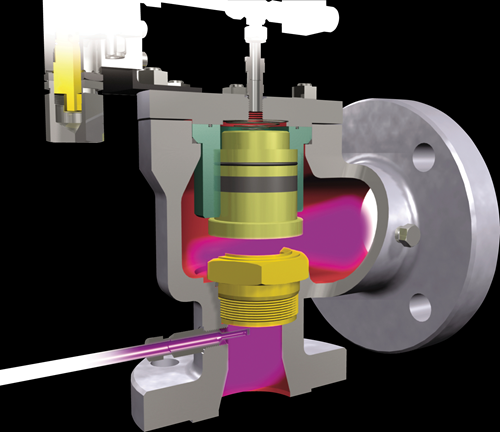

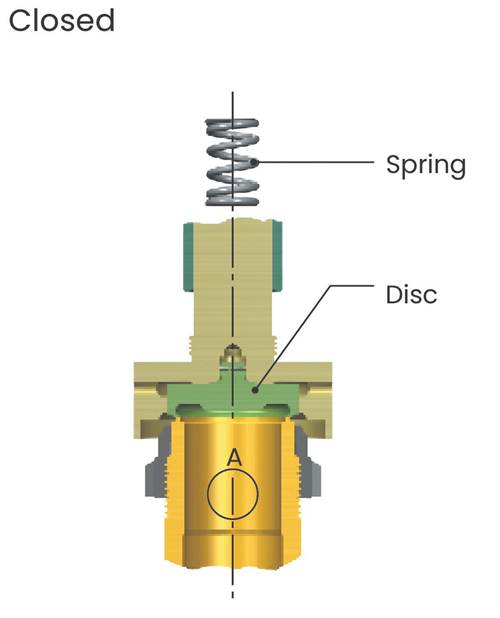

IMI Delivers More Than $18 Million USD in Orders for Hydrogen Projects

The company doubled its 2022 orders that supported hydrogen generation.

First National Legally Enforceable Drinking Water Standard for PFAS Passed

As part of the Administration’s commitment to combating PFAS pollution, EPA announces $1B investment through President Biden’s Investing in America agenda to address PFAS in drinking water.

#standards #water-wastewater

Blue Biofuels Announces Commencement of Engineering Study for Ethanol Plan

Engineering and design phase has started for its cellulose-to-sugar ethanol facility

EIG MidOcean Energy Completes Acquisition of Tokyo Gas' Interest in Australian LNG Projects

The acquisition includes Tokyo Gas’ interests in the Gorgon LNG, Pluto LNG and Queensland Curtis LNG projects.

Motion & Control Enterprises Acquires Daughtridge Sales Company Inc.

Acquisition is the company’s 10th since January 2023.